Heavy Duty Industrial Fans

Heavy Duty Solutions

Southern Africa Distribution Partner

Apex Engineering (PTY) Ltd is Sodeca’s authorised distributor for the Southern African region.

We supply key models locally, size systems to SANS 10400-T, and handle installation and after-sales support.

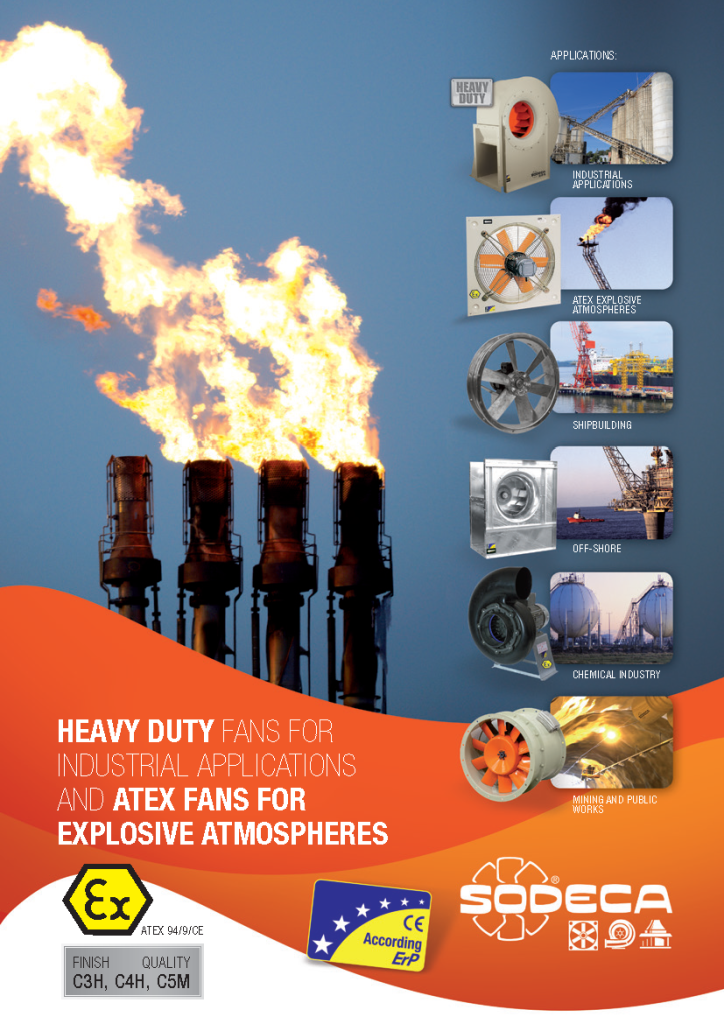

HEAVY DUTY FAN SYSTEMS

For extreme pressure, dust and vibration in industrial environments

Sodeca’s Heavy Duty Fans are purpose-built for the kind of environments where standard industrial fans give up: deep-level mine headings, solvent-laden paint lines, kiln exhausts and offshore engine rooms.

Every component is over-specified to keep airflow stable, maintenance predictable and total cost of ownership low.

1. Reinforced steel casings – up to 8mm wall thickness

Heavy-gauge tube or scroll housings resist vibration, blast shock and shaft-wall impacts, protecting the rotor from distortion and keeping tip clearances tight for maximum efficiency.

2. High-pressure impeller technology

– Tubular axial (HTP): cast-aluminium aerofoil blades pitched to deliver up to 1 480 Pa without stall.

– Centrifugal (CASB / CMRS): backward-curved steel wheels shaped to maintain >70 % total efficiency through dusty or humid air streams.

3. Motor options for any grid or ambient

Direct-drive fans ship with IE3 motors as standard, IE4 on request (75–200 kW). Belt-drive models isolate the motor from hot or contaminated air, making +70 °C operation routine. 525 V mining and 60 Hz offshore windings available ex-factory.

4. Corrosion & abrasion protection

Multi-stage coating—zinc-rich primer plus polyurethane top-coat—achieves C3H as standard, upgradeable to C5M or full stainless steel for coastal platforms and acid fumes. Salt-spray tested >1 500 h to ISO 12944.

5. Optional ATEX Category 2 execution

Where explosive gas or dust cannot be avoided, the same heavy-duty platform can be ordered with copper sacrificial rings, antistatic paint and Ex-rated motors certified to EN 14986.

Applications of Heavy Duty Industrial Fans

Heavy-duty industrial fans are essential in various industries for efficiently moving large volumes of air, aiding airflow, temperature control, and smoke extraction.

Mining & Tunnelling

Chemical / Petro-chem

Off-shore / Marine

Power Plants

Metal & Cement Factories

Heavy-Duty Fan Families

They give engineers a full menu of Heavy Duty Fans to match pressure, temperature, corrosion and installation constraints.

1. Axial Heavy Duty Fans

Read More

Sodeca’s axial line couples an 8 mm-wall steel tube with cast-aluminium aero-foil blades to deliver up to 156 000 m³/h and 1 480 Pa on the largest HTP model—ideal for long mine drifts, tunnel boosters and high-loss process ducts. When the same impeller technology is mounted on a curb plate with a weather hood it becomes the HTMH roof fan, moving 67 000 m³/h at roughly 550 Pa straight off the roof. Both executions share direct-drive IE3/IE4 motors, reversible pitch (supply or extract) and optional C4H / C5M coatings for coastal or offshore duty.

2. Centrifugal Heavy Duty Fans

Read More

For systems that need stable pressure through filters, bends or hot, dusty air, the centrifugal range offers two build paths. CASB and CMRS use heavy-gauge steel scrolls and backward-curved wheels to reach 57 500 m³/h at 1 300 Pa; belt-drive “X” variants keep the motor out of the airstream, allowing continuous operation at 150 °C. Where corrosive fumes would destroy coated steel, the CPV series swaps the housing and impeller for moulded polypropylene with stainless hardware, protecting fans in acid pickling, battery production and wastewater scrubbers—while still accepting optional ATEX Category 2 certification for mixed gas-and-dust zones.

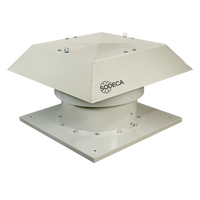

3. Roof-Mounted Heavy Duty Fans

Read More

The brochure’s dedicated roof group re-emphasises the HTMH design—essentially an axial fan factory-fitted to a square base and hood so it drops straight onto industrial roofs without extra ductwork. Its reversible impeller, IP55/Class F motor range and C4H/C5M coating system make it a space-saving alternative to side-wall or ducted units for foundries, warehouses and coastal process halls that still need heavy-duty airflow performance.

Features & Benefits of Sodeca Heavy Duty Fans

1. 8mm-wall steel or optional stainless casings – long life in abrasive or corrosive flows.

2. Copper or aluminium sacrificial tip strips on ATEX variants – spark-free for mixed gas/dust areas.

3. Dynamic balancing to ISO 1940 (G 6.3) – vibration kept <2.5 mm/s RMS, protecting bearings.

4. C3H, C4H or C5M paint systems – survives >1 500 h salt-spray (off-shore rigs, coastal power plants).

5. External grease points & split housings – maintenance in half the downtime.

SODECA Heavy Duty FAN RANGE

High Pressure Tubular Axial Extract Fan Range

High pressure, extremely robust tubular axial fans, specially designed for mining installations or in applications with large load losses.

HTP-90-4T-7.5 IE3

Airflow: 27450 m3/h

Max Static Pressure: 685 Pa

Power Rating: 5.5 Kw

HTP-90-4T-10 IE3

Airflow: 32500 m3/h

Max Static Pressure: 650 Pa

Power Rating: 7.5 Kw

HTP-90-4T-15 IE3

Airflow: 42200 m3/h

Max Static Pressure: 650 Pa

Power Rating: 11 Kw

HTP-90-4T-20 IE3

Airflow: 50050 m3/h

Max Static Pressure: 725 Pa

Power Rating: 15 Kw

HTP-90-4T-25 IE3

Airflow: 54550 m3/h

Max Static Pressure: 750 Pa

Power Rating: 18.5 Kw

HTP-90-4T-30 IE3

Airflow: 61750 m3/h

Max Static Pressure: 775 Pa

Power Rating: 22 Kw

HTP-100-4T-15 IE3

Airflow: 46100 m3/h

Max Static Pressure: 768 Pa

Power Rating: 11 Kw

HTP-100-4T-20 IE3

Airflow: 56300 m3/h

Max Static Pressure: 737 Pa

Power Rating: 15 Kw

HTP-100-4T-25 IE3

Airflow: 59900 m3/h

Max Static Pressure: 745 Pa

Power Rating: 18.5 Kw

HTP-100-4T-30 IE3

Airflow: 69900 m3/h

Max Static Pressure: 726 Pa

Power Rating: 22 Kw

HTP-100-4T-40 IE3

Airflow: 80446 m3/h

Max Static Pressure: 762 Pa

Power Rating: 30 Kw

HTP-125-4T-40 IE3

Airflow: 80887 m3/h

Max Static Pressure: 1431 Pa

Power Rating: 30 Kw

HTP-125-4T-50 IE3

Airflow: 96800 m3/h

Max Static Pressure: 1441 Pa

Power Rating: 37 Kw

HTP-125-4T-60 IE3

Airflow: 105049 m3/h

Max Static Pressure: 1487 Pa

Power Rating: 45 Kw

HTP-125-4T-75 IE3

Airflow: 127800 m3/h

Max Static Pressure: 1480 Pa

Power Rating: 55 Kw

HTP-125-4T-100 IE3

Airflow: 147350 m3/h

Max Static Pressure: 1460 Pa

Power Rating: 75 Kw

HTP-125-4T-125 IE3

Airflow: 156400 m3/h

Max Static Pressure: 1440 Pa

Power Rating: 90 Kw

Product Catalogues

Need a heavy-duty ventilation solution?

Tailored Solutions That Meet Industry Standards

Upload your airflow (m³/h) and pressure (Pa) specs, select the right fan and send a formal quote.

Heavy Duty Fans FAQ’s

What classifies a fan as “heavy duty”?

Reinforced casings, high-grade bearings, and certification to ISO 1940 vibration G 6.3 allow continuous operation at high static pressure without fatigue.

How much pressure can Sodeca heavy duty fans generate?

The HTP axial range tops out at ≈ 1 480 Pa, while CMRS centrifugals reach 1 300 Pa—sufficient for deep-shaft mining and long-duct runs.

Can heavy duty fans be supplied with ATEX certification?

Yes—HTP and CASB families are available in ATEX Category 2 executions for Zones 1/21 gas or dust, built to EN 14986.

Which motor efficiencies are offered?

IE3 motors are standard; IE4 is available from 75 kW upward, trimming roughly 300 kWh per fan annually on typical duty.

What maintenance is required?

Annual bearing regrease, vibration check and inspection of coating integrity; split scrolls or removable cowls speed strip-down.

Full Turnkey High-Pressure Industrial Extraction Systems, including Supply & Install.

- Cape Town, South Africa

- Johannesburg, South Africa

- Durban, South Africa

- info@apexengineering.co.za

- sales@apexengineering.co.za

- tenders@apexengineering.co.za