ATEX – Certified Fans for Explosive Atmospheres

Sodeca ATEX Solutions

Southern Africa Distribution Partner

Apex Engineering (PTY) Ltd is Sodeca’s authorised distributor for the Southern African region.

We stock key models locally, size systems to SANS 10400-T, and handle installation and after-sales support.

SODECA ATEX EXTRACTION SYSTEMS

For Zone 1 & 21 hazardous areas

SODECA ATEX extraction fans are engineered in accordance with European explosive-atmosphere standards:

Directive 2014/34/EU (ATEX 114)

Governs equipment and protective systems intended for use in explosive atmospheres across the EU and is recognised by South-African authorities.

EN 14986 : 2017 – Fans for explosive atmospheres

Defines design, construction, testing and marking requirements for complete fan units handling flammable gas, vapour, mist or dust.

IEC 60079 series – Electrical equipment

Covers Ex d, Ex e, Ex n, Ex t protection concepts and zone classification (IEC 60079-10-1/2).

ISO / IEC 80079-36 – Non-electrical equipment

Specifies how non-electrical ignition sources (e.g. rotating fan blades) must be designed and tested for all EPLs (Ga / Gb / Gc).

EN 1127-1 : 2019 – Explosion prevention & protection

Provides the risk-assessment framework that underpins the above product standards.

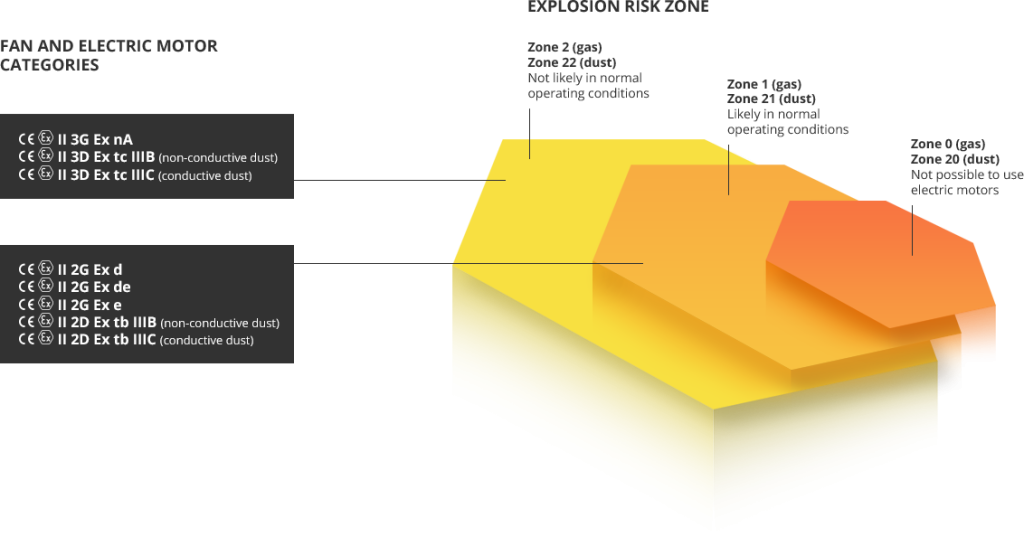

Explosion-Risk Mitigation by Ventilation

A single spark in a paint booth, sugar mill or petro-chemical line can set off an explosion. ATEX rules exist to remove that spark risk before it starts.

Europe’s Directive 2014/34/EU lays out the legal framework, while EN 14986:2017 spells out how fans must be built so their blades, casings and motors can’t ignite a flammable mix of gas or dust.

1. Non-sparking parts

Soft copper or aluminium strips sit at the impeller tip; if the blade ever touches the housing, the soft metal rubs rather than strikes, preventing sparks.

2. Ex-rated motor

Motors are temperature-classed (e.g., T4 = 135 °C surface max). The motor is sealed or built so that any heat or arcs stay inside. Different “Ex” codes (db, eb, tb) tell you which safety method is used.

3. Anti-static paint & earthing

The casing is coated and grounded so dust can’t build up an electric charge. Entire assembly is designed per EN 14986 for explosive atmospheres.

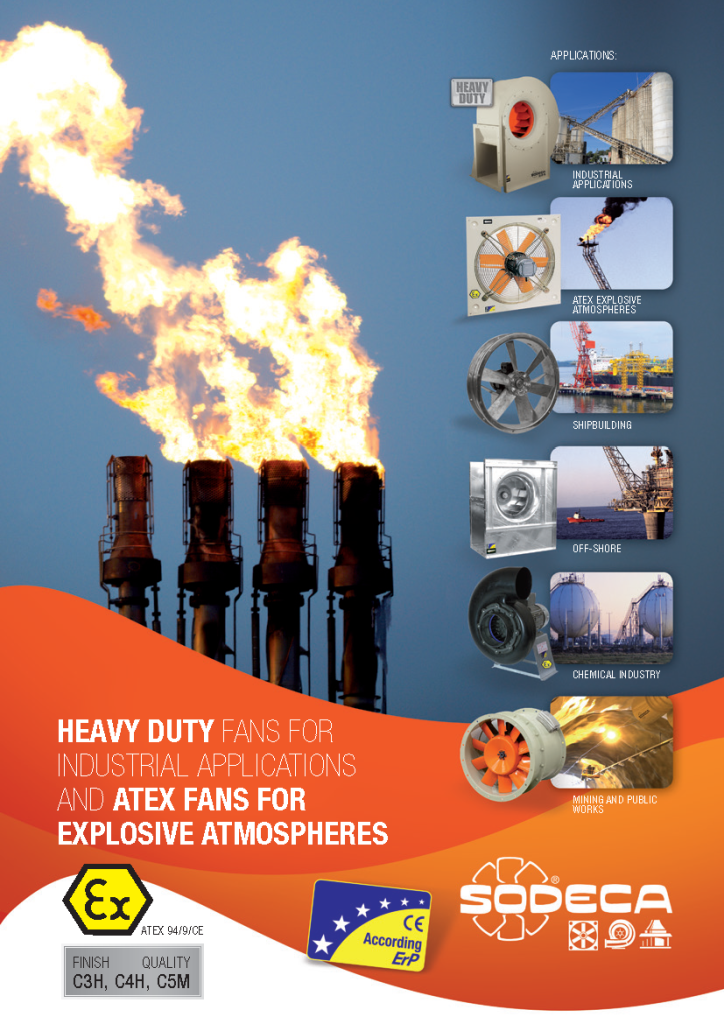

Features & Benefits of Sodeca ATEX Fans

1. Compliance with EN 14986 & Directive 2014/34/EU – recognised by SA insurers.

2. Spark-proof construction prevents ignition sources.

3. Corrosion-resistant C3H–C5M coating for coastal plants.

4. High-efficiency impellers reduce Eskom electricity spend.

5. Local stock up to Ø 630 mm shortens project lead-times.

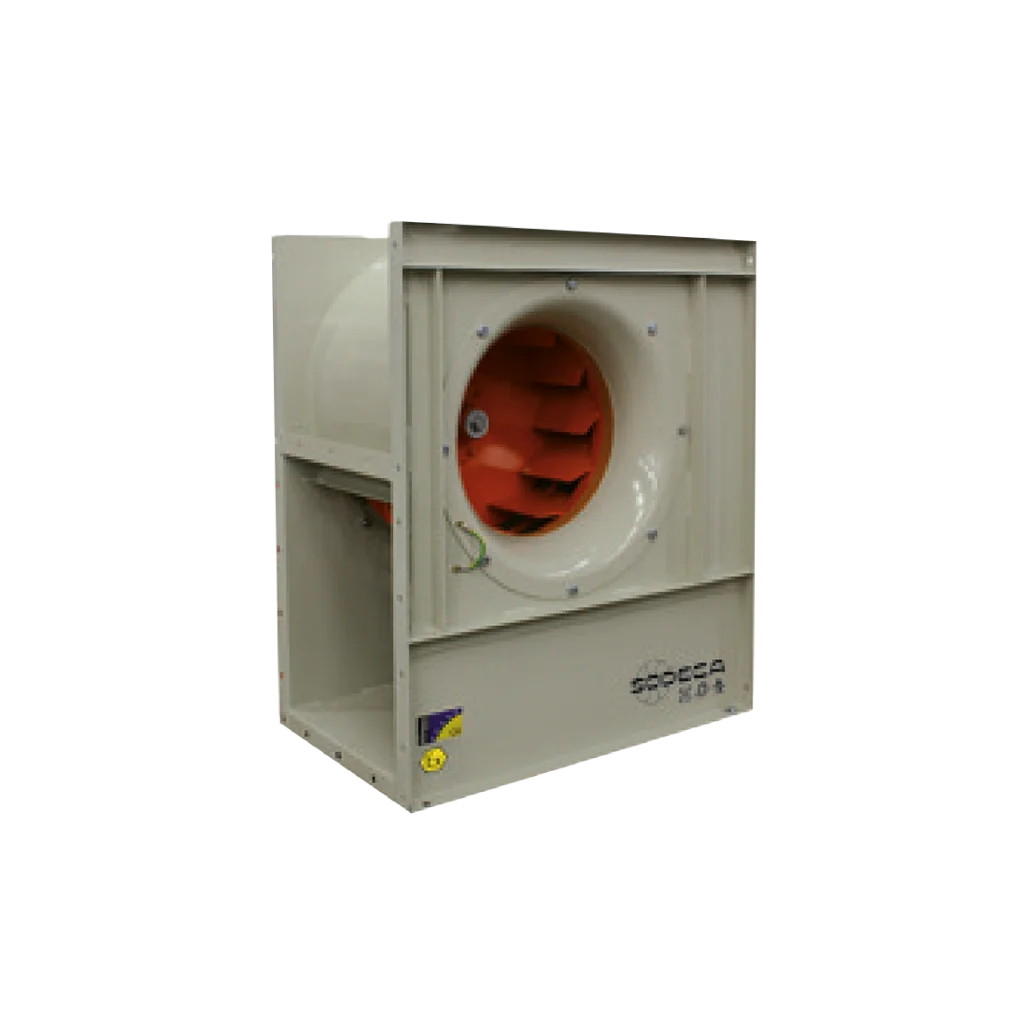

SODECA ATEX FAN RANGE

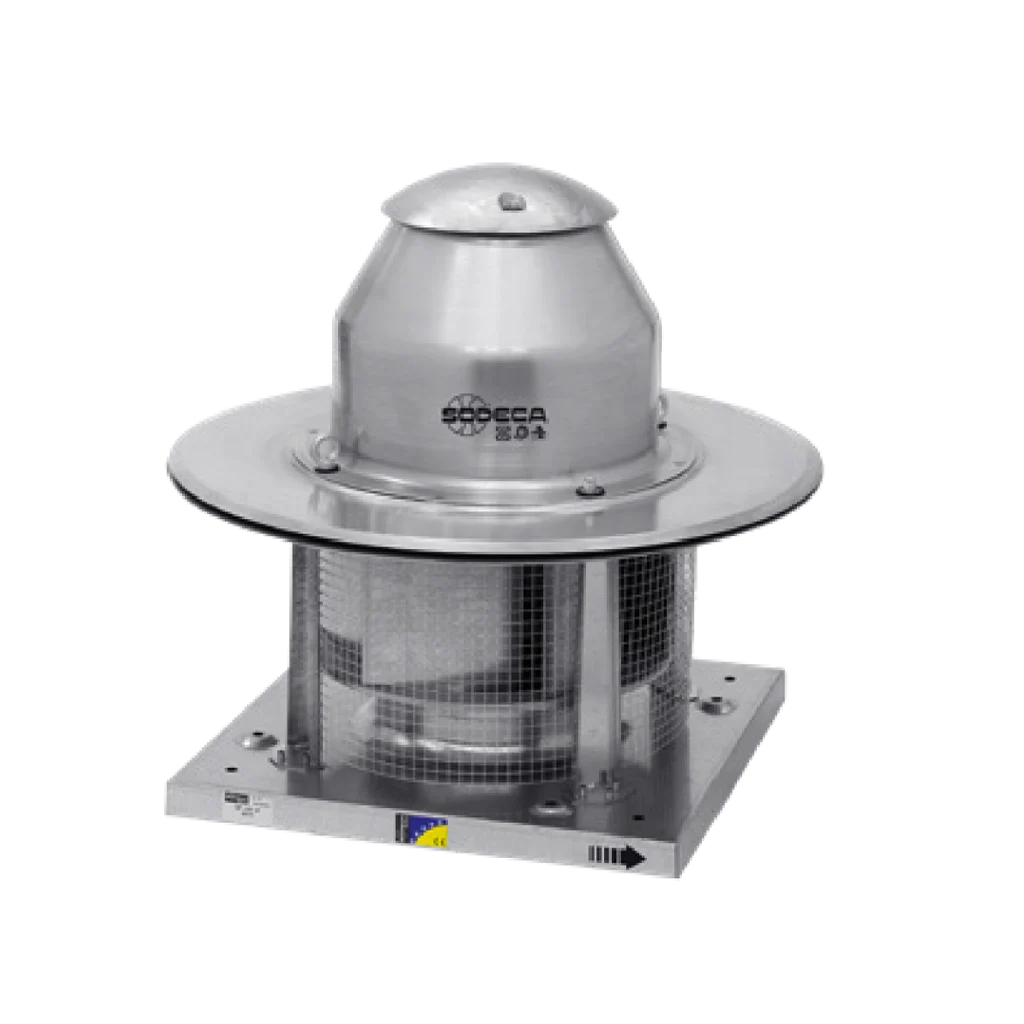

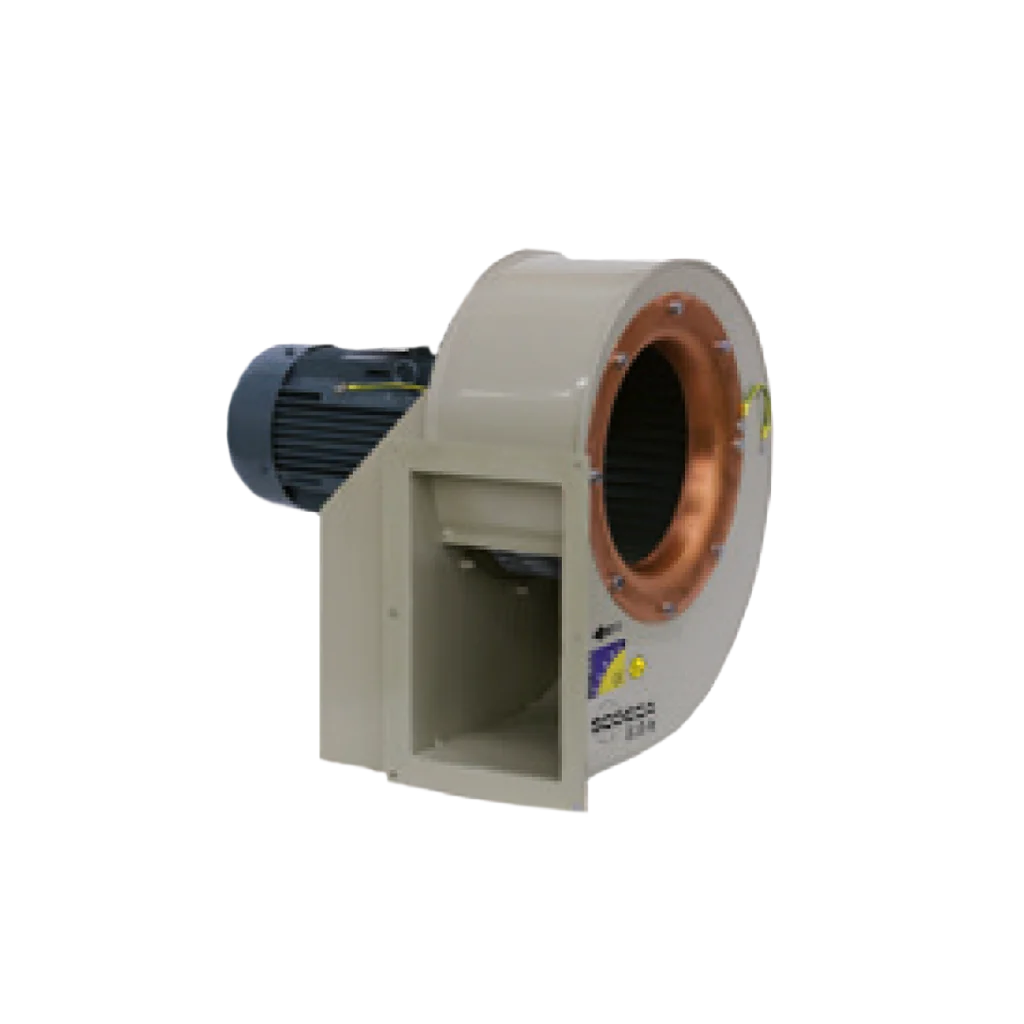

HCDF

Read More

Applications of ATEX Fans

There are many applications that may require fans prepared to work in explosive atmospheres.

In general, any application that takes place in a zone with a risk of explosion.

Oil Refineries

Chemical and Pharmaceutical industries

Paint and varnish booths

Agri-food industry

Wood and carpentry industry

Fuel warehouses (liquid or gaseous)

Shipbuilding

Off-shore

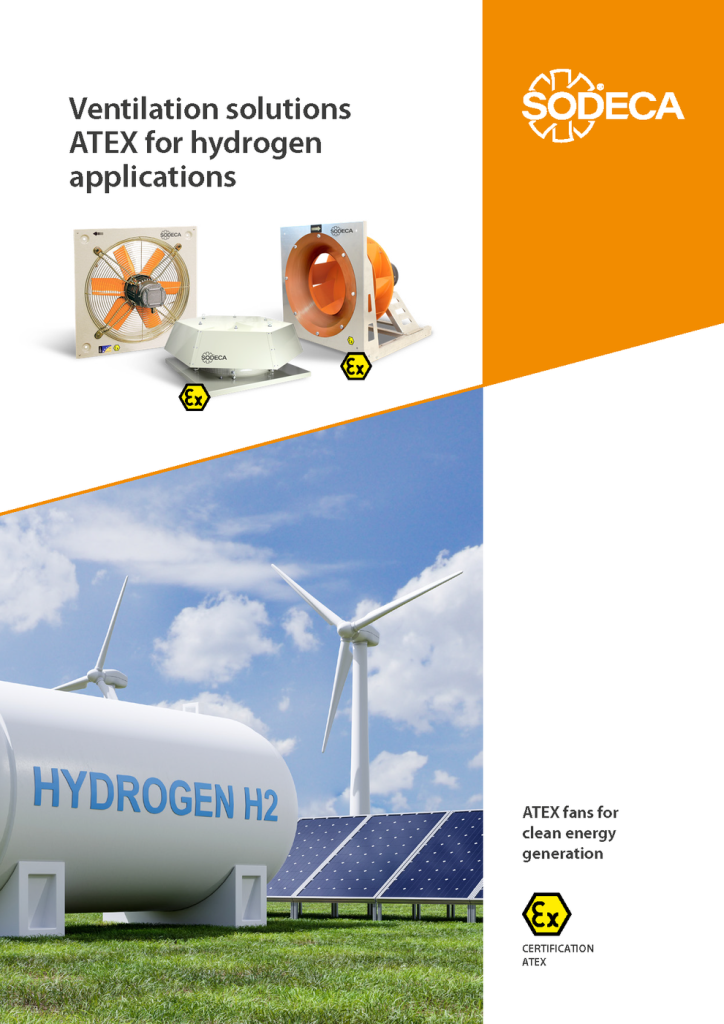

Green hydrogen electrolysers

Get Expert Design Assistance for Your ATEX Ventilation Project

Tailored Solutions That Meet Industry Standards

Apex Engineering provides turnkey ATEX ventilation solutions that meet SANS 10400-T and EU directives.

Upload your P&IDs or zoning drawings and our engineers will size the correct Sodeca fan and issue the compliance pack.

SODECA ATEX Fans FAQ’s

What is ATEX and why is it critical for explosive-atmosphere extraction?

ATEX (Directive 2014/34/EU) sets mandatory safety rules for equipment used in explosive atmospheres; Sodeca fans meet these rules and are accepted by South-African authorities.

How do ATEX fans prevent ignition during extraction?

EN 14986 demands non-ferrous tip rings, verified clearances and Ex-rated motors, eliminating sparks while air is extracted.

Can ventilation really de-classify a Zone 1 area?

Yes – continuous extraction that keeps gas or dust below 25 % LEL allows re-classification to Zone 2/22, reducing Ex hardware costs.

Which ATEX marking covers both gas and dust?

Specify dual “GD” coding, e.g. II 2 GD Ex db eb h IIB T4/T135 °C Gb Db, protecting Zones 1 & 21 simultaneously.

Does ATEX equipment need special maintenance?

Periodic checks under IEC 60079-17 ensure clearances, earthing straps and coatings remain within EN 14986 limits; Apex offers annual audits.

Full Turnkey Explosive Atmospheric Ventilation Systems, including Supply & Install.

- Cape Town, South Africa

- Johannesburg, South Africa

- Durban, South Africa

- info@apexengineering.co.za

- sales@apexengineering.co.za

- tenders@apexengineering.co.za