Ventilation Systems for Tunnels

Tunnel Ventilation Solutions

Southern Africa Distribution Partner

Apex Engineering (PTY) Ltd is Sodeca’s authorised distributor for the Southern African region.

Ventilation systems designed for underground infrastructures such as tunnels, railways or undergrounds.

Tunnel Ventilation Portfolio

Four specialised families—jet, axial main, auxiliary, and BOXTUNEL controls—cover every airflow, pressure and control need from day-to-day ventilation to full fire-smoke extraction.

1. Jet Fans

Read More

Compact steel tubes with reversible aluminium blades and built-in silencers. They generate 120 – 2 850 N thrust (up to 360 000 m³/h) and carry F300/F400 EN 12101-3 fire ratings, making them the work-horse for longitudinal tunnel airflow and smoke extraction.

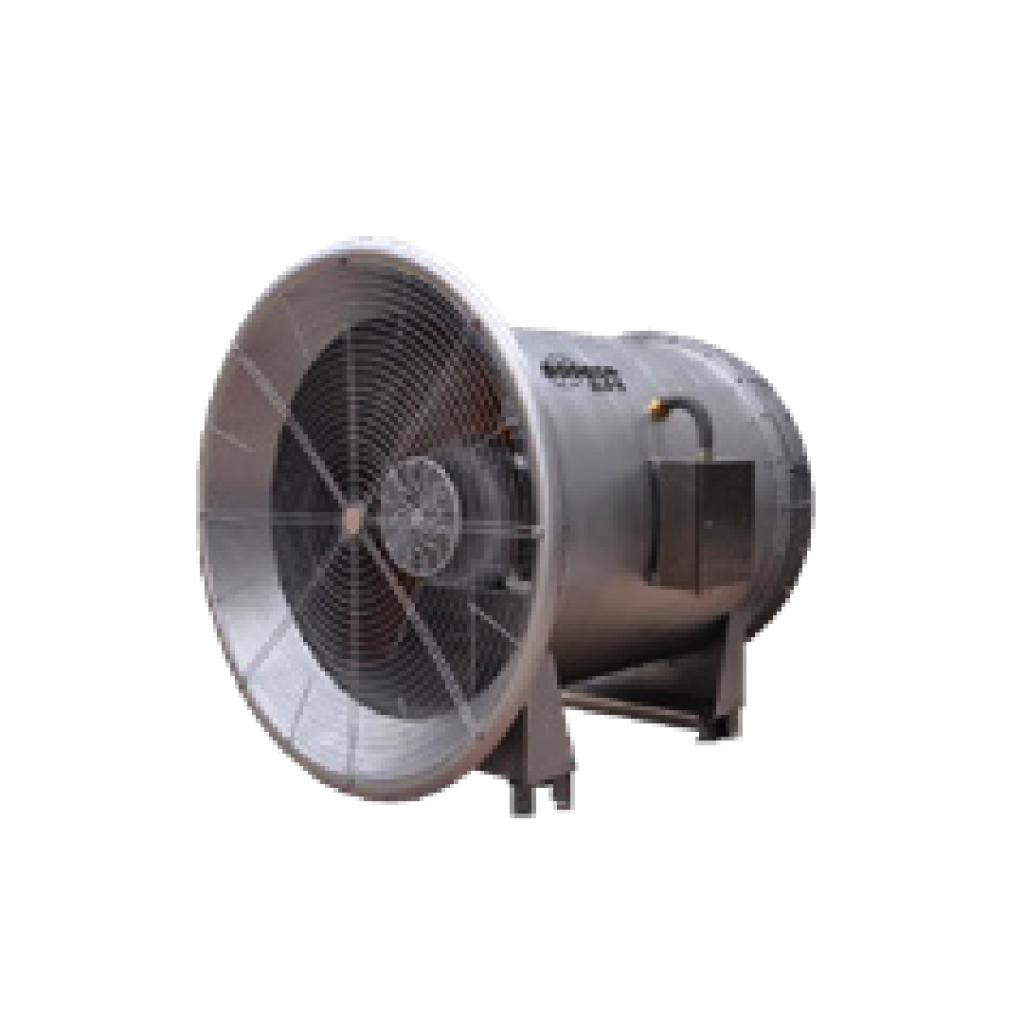

2. Axial Main Fans

Read More

Large-diameter cylindrical units (Ø 450–3 150 mm) that move up to 1 000 000 m³/h at 4 000 Pa. Fully reversible aero-foil blades and inlet-cone silencers suit them to fresh-air supply or exhaust shafts where high volume and fire-safe performance are essential.

3. Control & Ancillaries (BOXTUNEL)

Read More

A PLC panel with VSDs, MODBUS connectivity, temperature-rated dampers, silencers and thrust-rated mounts. It synchronises comfort and fire speeds, ties into SCADA, and delivers a turnkey compliance pack alongside the fans.

Tunnel Ventilation Applications

Tunnels

Mining

Stations

Tunnel Ventilation Fan RANGE

THT/IMP-C Jet Fan Range

Jet fans designed for tunnel ventilation. Smoke Certified 400 ºC/2h and 300 ºC/2h

THT/IMP-C-UNI-56-4T-2 IE3

Airflow: 14550 m3/h

Thrust: 76 N

Impulsion speed 16 m/s

Power Rating: 1.5 Kw

THT/IMP-C-UNI-56-2T-12 IE3

Airflow: 29500 m3/h

Thrust: 312 N

Impulsion speed 38 m/s

Power Rating: 9.2 Kw

THT/IMP-C-UNI-63-4T-3 IE3

Airflow: 21550 m3/h

Thrust: 132 N

Impulsion speed 19 m/s

Power Rating: 2.2 Kw

THT/IMP-C-UNI-63-2T-20 IE3

Airflow: 40050 m3/h

Thrust: 455 N

Impulsion speed 37 m/s

Power Rating: 15 Kw

THT/IMP-C-UNI-71-4T-4 IE3

Airflow: 28550 m3/h

Thrust: 182 N

Impulsion speed 20 m/s

Power Rating: 3 Kw

THT/IMP-C-UNI-80-4T-5.5 IE3

Airflow: 36900 m3/h

Thrust: 239 N

Impulsion speed 20 m/s

Power Rating: 4 Kw

THT/IMP-C-UNI-90-4T-10 IE3

Airflow: 52000 m3/h

Thrust: 375 N

Impulsion speed 23 m/s

Power Rating: 7.5 Kw

THT/IMP-C-UNI-100-4T-15 IE3

Airflow: 66500 m3/h

Thrust: 497 N

Impulsion speed 24 m/s

Power Rating: 11 Kw

THT/IMP-C-UNI-125-4T-30 IE3

Airflow: 98100 m3/h

Thrust: 692 N

Impulsion speed 22 m/s

Power Rating: 22 Kw

THT/IMP-C-UNI-125-4T-50 IE3

Airflow: 156400 m3/h

Thrust: 1101 N

Impulsion speed 28 m/s

Power Rating: 37 Kw

Tunnel Ventilation Operating Concepts

Two Modes, One Integrated System

All tunnel models are certified F400-120 — they run 120 min at 400 °C without loss of performance.

Need Tunnel Ventilation Systems?

Apex Engineering provides tunnel ventilation solutions that meet SANS 10400-T and EU directives.

Tunnel Ventilation System Architectures

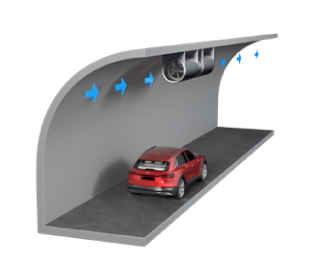

Longitudinal

Jet fans drive airflow end-to-end.

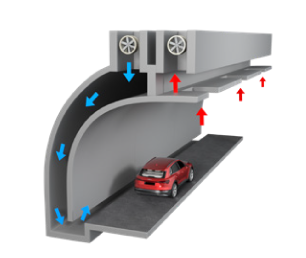

Transverse

Separate supply & extract ducts feed diffuser slots.

Semi-transverse

Hybrid of the two for medium lengths or retrofits.

Compliance & Quality

EN 12101-3:2015

F200 / F300 / F400 smoke-and-heat certification

ISO 13350 & ISO 5801

Aerodynamic, thrust & noise tests

ISO 1940-1 (G 6.3)

Dynamic rotor balance

EU Eco-design IE3/IE4

Energy efficiency (Reg. 640/2009)

ISO 9001:2015

Factory QA & traceability

Accessories & Installation

Jet fans arrive with galvanised brackets, anti-vibration mounts and safety anchors sized to thrust.

1. High-temperature back-draught dampers.

2. Split silencers to ≤ 75 dB(A) @ 10 m in comfort mode

3. C5-M epoxy or stainless build for coastal tunnels

4. BOXTUNEL PLC with fibre or Ethernet gateways for SCADA tie-in

Tunnel Ventilation FAQ’s

Why choose jet fans over ducted systems?

Jet fans use kinetic energy to move air—no costly ducting—making them ideal for road tunnels up to ~3 km.

What fire rating do the fans carry?

All tunnel fans are certified F200, F300 or F400 under EN 12101-3, meaning they run for 2 h at 200 °C, 300 °C or 400 °C as specified.

Are reversible fans really equal in both directions?

Yes. Sodeca’s reversible jet and axial models match forward and reverse thrust within ±10 % by using symmetric aero-foil blade geometry.

Can one system handle both ventilation and smoke?

F400-rated motors and BOXTUNEL control shift from low-speed ventilation to high-speed smoke extraction automatically.

How is corrosion handled in coastal tunnels?

Fans can be specified in galvanised or stainless steel, plus epoxy paint; anti-corrosive finishes are recommended where chloride levels are high.

What about noise limits?

Built-in silencers plus optional split silencers reduce breakout to 75 dB(A) @ 10 m under comfort duty.

Full ventilation systems for tunnels, including supply & install.

- Cape Town, South Africa

- Johannesburg, South Africa

- Durban, South Africa

- info@apexengineering.co.za

- sales@apexengineering.co.za

- tenders@apexengineering.co.za